A mose wright is a large timber or metal frame used to lift and move heavy objects, typically mounted on wheels or a skid. It is commonly employed in construction, shipbuilding, and industrial settings.

Mose wrights are crucial for moving massive objects safely and efficiently. They reduce manual labor, prevent accidents, and increase productivity. Historically, the invention of the mose wright revolutionized construction practices, enabling the construction of larger and more complex structures.

This article will delve into the design, operation, and safety aspects of mose wrights, exploring their applications, limitations, and recent advancements in the field.

- Unveiling The Truth Behind Buscar Kid And His Mom Video Original

- Movierulz Kannada 2023 Your Ultimate Guide To The Latest Movie Scene

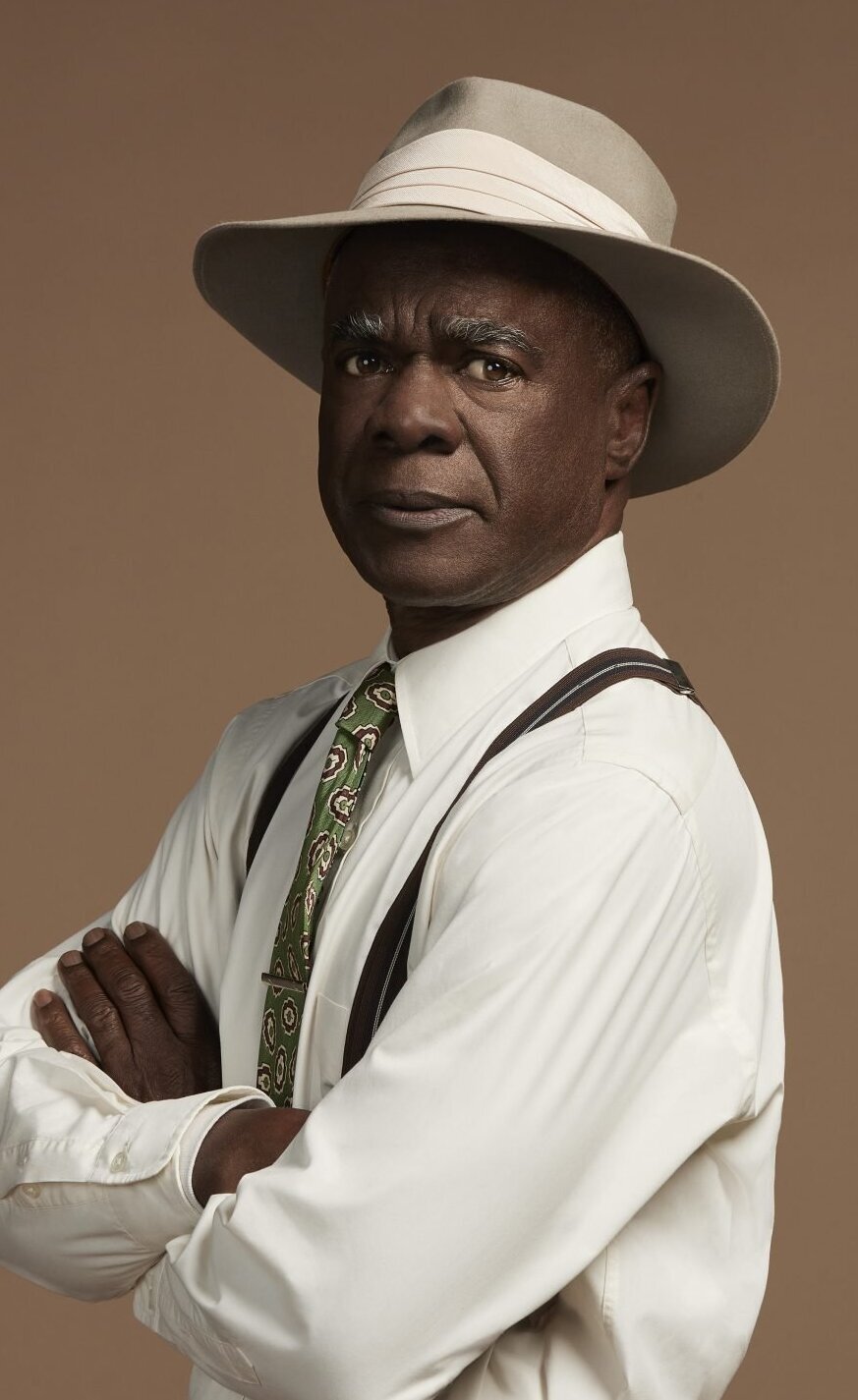

Mose Wright

Understanding the essential aspects of mose wrights is crucial for their safe and effective operation. These aspects encompass various dimensions, including:

- Design

- Operation

- Safety

- Applications

- Limitations

- Maintenance

- Inspection

- Regulations

These aspects are interconnected and influence the overall performance and reliability of mose wrights. A comprehensive understanding of each aspect is essential for ensuring the safe and efficient lifting and moving of heavy objects.

Design

The design of a mose wright is a critical aspect that determines its functionality, safety, and efficiency. It encompasses various factors, including the materials used, the structural configuration, and the incorporation of safety features.

- Miaz Girthmaster The Ultimate Guide To Understanding And Maximizing Your Potential

- Jameliz Benitez Smith A Comprehensive Look Into Her Life And Career

- Materials

Mose wrights are typically constructed from high-strength materials such as steel, aluminum, or timber. The choice of material depends on the weight capacity, durability, and cost requirements. - Structural Configuration

The structural configuration of a mose wright involves the arrangement of its components, such as the frame, wheels, and lifting mechanism. Different configurations are suitable for specific applications, such as overhead lifting or mobile lifting. - Safety Features

Mose wrights incorporate various safety features to prevent accidents and protect operators. These features include overload protection systems, anti-tipping mechanisms, and emergency stop buttons. - Ergonomics

Ergonomics plays a crucial role in the design of mose wrights, ensuring that they are easy and comfortable to operate. Factors such as handle placement, seat design, and visibility are considered to minimize operator fatigue and strain.

By considering these design aspects, manufacturers can create mose wrights that are safe, efficient, and meet the specific requirements of various applications.

Operation

The operation of a mose wright encompasses the processes and procedures involved in its safe and efficient functioning. It includes various components and activities, ranging from preparation to maintenance.

- Setup

Prior to operation, a mose wright must be properly set up, ensuring that all components are securely assembled and the lifting area is clear of obstructions. - Loading

The load must be carefully attached to the lifting mechanism, ensuring that it is balanced and secure. Factors such as weight distribution and load capacity must be considered. - Lifting

The lifting operation involves using the mose wright's mechanical system to raise the load. Proper techniques must be employed to prevent damage to the equipment or injury to personnel. - Transporting

If the load needs to be moved, the mose wright must be carefully maneuvered while maintaining stability and load control.

Understanding and adhering to proper operating procedures is crucial for the safe and effective use of mose wrights. Regular maintenance and inspections are also essential to ensure optimal performance and longevity.

Safety

Safety is a critical component of mose wright operations, ensuring the well-being of operators, bystanders, and the equipment itself. Without proper safety measures, mose wrights can pose significant risks due to their heavy loads and potential for accidents.

Mose wrights incorporate various safety features to mitigate these risks. These features include overload protection systems, which prevent the equipment from lifting loads beyond its capacity, and anti-tipping mechanisms, which enhance stability during lifting and transporting. Regular maintenance and inspections are also crucial for ensuring the reliability and safety of mose wrights.

Understanding the connection between safety and mose wright is essential for their effective and responsible use. By adhering to safety procedures, operators can minimize risks, prevent accidents, and ensure the longevity of the equipment. This understanding extends to all aspects of mose wright operation, from setup and loading to lifting and transporting.

Applications

The relationship between Applications and Mose Wrights is a critical aspect in understanding the importance of these machines in various industries. Mose wrights find applications in diverse sectors, including construction, manufacturing, and transportation due to their ability to lift and move heavy objects safely and efficiently.

One of the key applications of mose wrights is in construction, where they are used for lifting and placing heavy materials such as concrete slabs, steel beams, and prefabricated structures. The use of mose wrights in construction enables faster and more efficient completion of projects, which ultimately contributes to cost savings and timely project delivery.

Mose wrights are also widely used in manufacturing industries, particularly in assembly lines and warehouses. They facilitate the movement of heavy machinery, goods, and materials, streamlining production processes and enhancing productivity. The ability of mose wrights to lift and transport heavy loads with precision makes them indispensable in manufacturing environments.

In summary, understanding the connection between applications and mose wrights provides valuable insights into the significance of these machines in various industries. By leveraging the capabilities of mose wrights, industries can improve efficiency, safety, and productivity, contributing to overall economic growth and development.

Limitations

Understanding the limitations of mose wrights is as important as recognizing their advantages. Mose wrights, while essential tools in various industries, have certain inherent limitations that must be considered to ensure safe and effective operation.

- Weight Capacity

Mose wrights have a finite weight capacity, and exceeding this limit can lead to structural failure and catastrophic accidents. It is crucial to carefully assess the weight of the load and ensure it is within the specified capacity of the mose wright. - Height Limitations

The height to which a mose wright can lift is limited by its design and the length of its lifting mechanism. This limitation can impact operations in high-rise construction or when working with tall structures. - Maneuverability

Mose wrights, especially larger models, can be challenging to maneuver in confined spaces or on uneven terrain. Their size and weight can limit their accessibility and require careful planning for transportation and operation. - Environmental Factors

Mose wrights can be affected by environmental factors such as wind, rain, and extreme temperatures. These factors can impact stability, visibility, and overall performance, requiring operators to take appropriate precautions.

Recognizing these limitations allows operators and supervisors to plan and execute lifting operations safely and efficiently. By understanding the weight capacity, height limitations, maneuverability constraints, and environmental factors, they can avoid potential risks and ensure the longevity of the equipment.

Maintenance

Maintenance plays a critical role in ensuring the safe and efficient operation of mose wrights. Regular maintenance helps prevent breakdowns, extends the equipment's lifespan, and reduces the risk of accidents. Mose wrights are complex machines with various components that require regular inspection, lubrication, and replacement to maintain optimal performance.

Neglecting maintenance can lead to premature wear and tear, compromising the structural integrity of the mose wright and potentially causing catastrophic failures. Proper maintenance involves adhering to manufacturer-recommended schedules for inspections, servicing, and component replacements. This includes checking hydraulic systems, wire ropes, brakes, and electrical components for signs of wear, damage, or corrosion.

Real-life examples of maintenance practices in mose wright operations include regular greasing of moving parts, periodic inspections of load-bearing components, and timely replacement of worn or damaged parts. Maintenance personnel play a crucial role in identifying potential issues early on, preventing minor problems from escalating into major breakdowns. By understanding the connection between maintenance and mose wright performance, operators and maintenance teams can proactively address potential issues, ensuring the equipment's reliability and longevity.

Inspection

Inspection plays a crucial role in the safe and efficient operation of mose wrights. Regular inspections help identify potential issues, prevent breakdowns, and ensure the equipment's reliability and longevity. Mose wrights are complex machines with various components that require regular examination to maintain optimal performance.

Inspecting mose wrights involves examining various components, including hydraulic systems, wire ropes, brakes, and electrical components, for signs of wear, damage, or corrosion. Thorough inspections help identify potential problems early on, preventing minor issues from escalating into major breakdowns. Real-life examples of inspection practices in mose wright operations include daily visual inspections before use, periodic non-destructive testing to detect hidden defects, and comprehensive overhauls at specified intervals.

Understanding the connection between inspection and mose wright performance is essential for ensuring the equipment's safety and reliability. Regular inspections allow maintenance personnel to proactively address potential issues, preventing costly repairs and minimizing downtime. By adhering to manufacturer-recommended inspection schedules and following proper inspection procedures, operators can extend the lifespan of their mose wrights, reduce the risk of accidents, and maintain optimal performance.

Regulations

Regulations play a critical role in ensuring the safe and compliant operation of mose wrights. Stringent regulations are in place to safeguard operators, bystanders, and the equipment itself during lifting operations.

These regulations cover various aspects of mose wright use, including design, construction, inspection, maintenance, and operator certification. By adhering to these regulations, organizations can minimize risks, prevent accidents, and maintain a safe work environment. Real-life examples of regulations in mose wright operations include adherence to industry standards such as ASME B30.5, regular inspections by certified inspectors, and mandatory training and certification for operators.

Understanding the connection between regulations and mose wright performance is essential for organizations and individuals involved in lifting operations. By complying with regulations, organizations can demonstrate their commitment to safety, reduce liability, and foster a culture of responsible equipment use. Moreover, adhering to regulations helps ensure that mose wrights are operated within their design limits, minimizing wear and tear and extending their lifespan.

In conclusion, our exploration of mose wrights has illuminated their critical role in various industries, their inherent limitations, and the importance of maintenance, inspection, and adherence to regulations. Understanding these aspects is essential for the safe, efficient, and compliant operation of mose wrights.

Two main points stand out: firstly, the versatility of mose wrights in handling heavy lifting tasks across sectors. Secondly, the paramount importance of proper maintenance, regular inspections, and adherence to regulations to ensure safety, prevent accidents, and extend the equipment's lifespan.

- Baldwin Brothers Exploring The Legacy Of Hollywoods Most Talented Siblings

- Best Remote Iot Vpc Ssh Raspberry Pi Free Setup Guide